Thexpan®- thermodynamic sandwich panel

Thexpan® is a group of products based on a thermodynamic sandwich panel. They occur as a roof or as a sandwich panel wall. It is the only solution protected by patent law on the market which combines the sandwich panel with the heat exchanger creating one modern construction and insulation material.

Thexpan® sandwich panels can be used for various purposes – being a solar system, a roof with self-removal of snow, heat radiator and its absorber. They can also be the lower power source of the heat pump. All thanks to external and internal piping. Such a connection of a panel with a heat exchanger allows the combination of the shielding function of the panel with a technological function (heat absorption or heat emission) and as a result, reduction of investment and operating costs. Thexpan® sandwich panels are used in residential and industrial construction. The Thexpan® thermodynamic sandwich panel as the only wall / roof in the world can be used as the lower power source for heat pumps (alternatively or in addition to boreholes). Thexpan® sandwich panels are a hybrid of shielding building materials and extremely efficient heat exchangers. Thexpan® is made of two shielding sheets, heat exchanger tubes and polyurethane thermal insulation. Importantly, the pipes are laid directly under the sheet, in one-sided or two-sided manner, thanks to which they absorb or emit heat through the largest possible surface. The wall and the ceiling of the Thexpan® sandwich panel can be heated up or cooled down. The sun, air, stove or earth can be the source of energy. Thexpan® gives the opportunity to use each of them. In the Thexpan® plus version, the inner shielding layer (roof) is replaced with the OSB panel. This type of panel eliminates the need to break the thermal bridges by eliminating the sheet as a heat conductor. The absorption variation of the sandwich panel, in addition to shielding function, performs two basic functions:

- offtake of “heat” from external sheets from the walls and / or roofs heated by solar rays and ambient air.

- emission of “heat” to the external sheets of walls and / or roofs in winter.

Thanks to this, it is possible, among others, to take energy from the sun in order to obtain hot utility water in the summer or to remove snow in the winter. In cooperating with the heat pump, Thexpan® also utilises air temperature. It can then “work” at any season of the year and time, regardless of the sun.

Types of panels

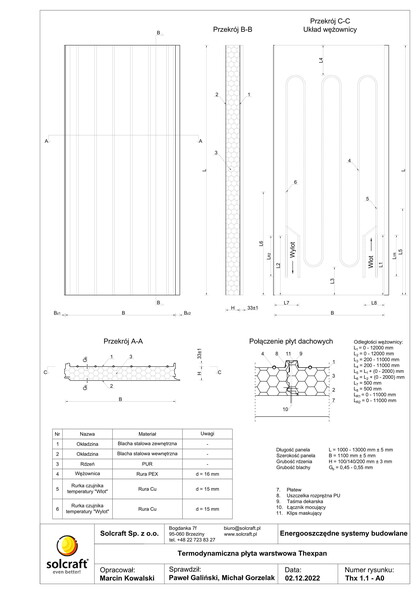

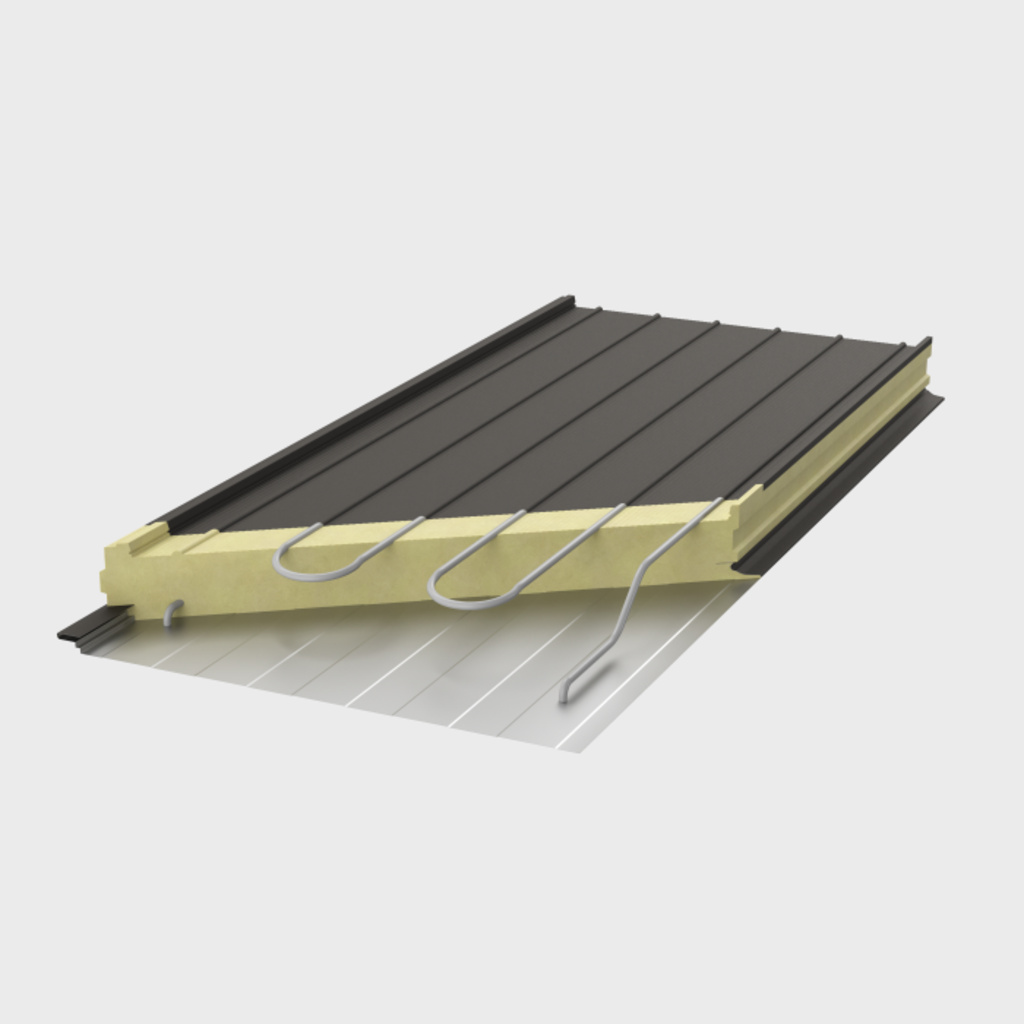

Thexpan®

The “Classic” Thexpan® is made of two protective sheets and a polyurethane core. Under the surface of the top sheet there is placed a heat exchanger in the “pipe coil” system. Each panel has, in the lower lining, an inlet and outlet opening in order to connect the exchanger with the heat offtake installation. The installation of the exchanger has an “installation reserve” to be processed by the installer. The panel also has a space for entering the external sheet temperature sensor. The installation of the exchanger is prepared for connecting it in parallel with other heat exchangers (in other panels): through the supply and partition collectors.

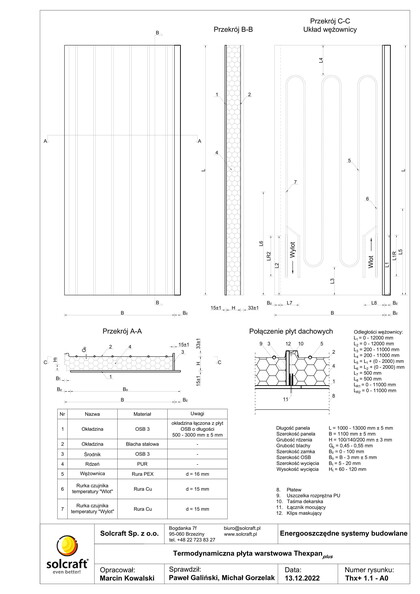

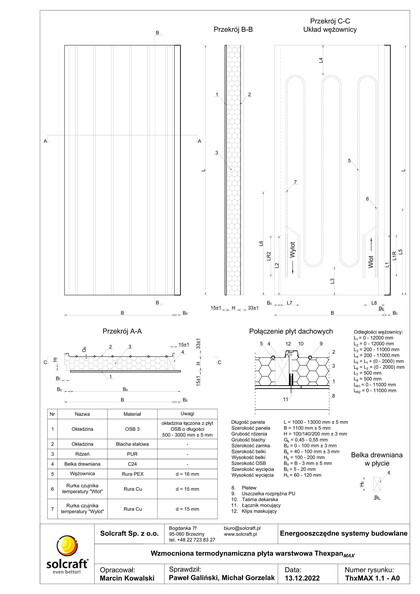

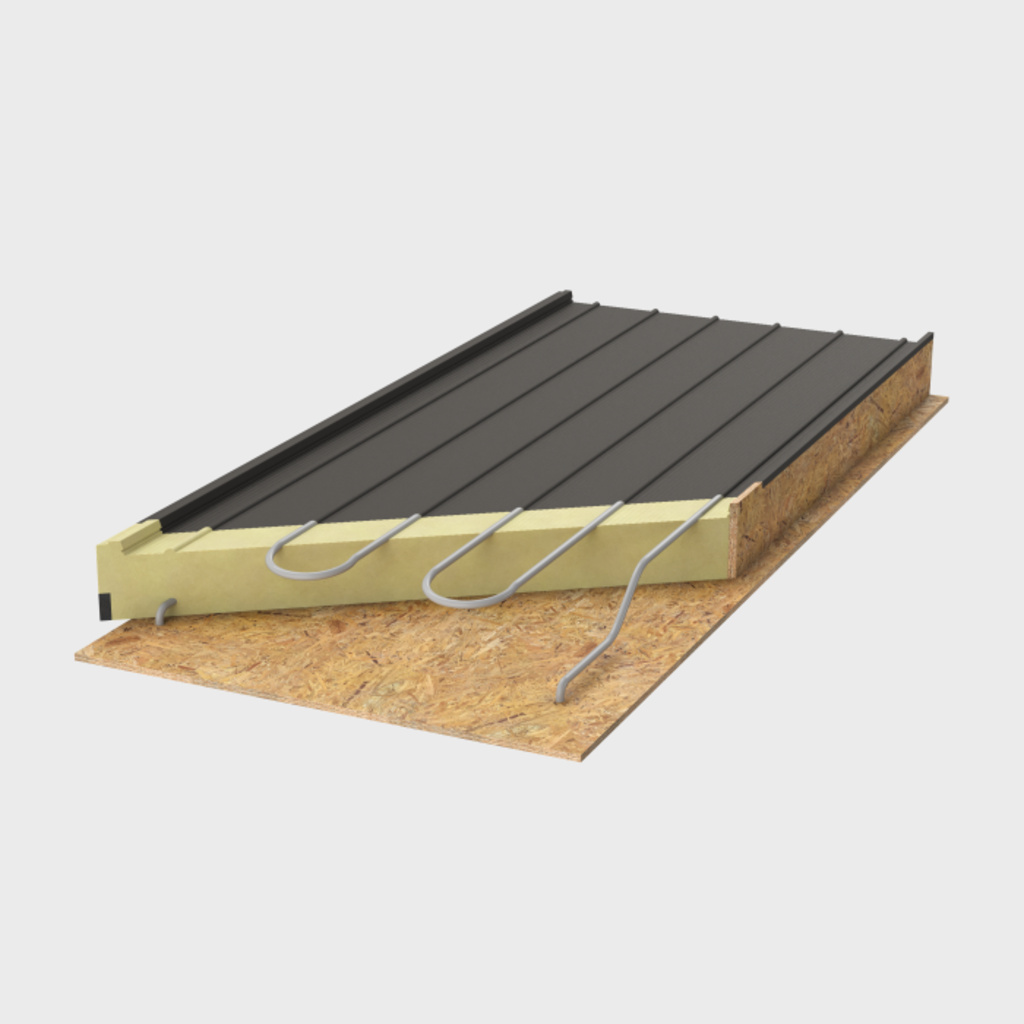

Thexpanplus®

The Thexpan® variant is Thexpanplus® built from one – top shielding sheet, polyurethane core and internal lining of OSB. Under the surface of the upper sheet there is a heat exchanger in the “pipe coil” system. Each panel has an inlet and outlet opening in the lower lining in order to connect the exchanger with the heat offtake installation. The installation of the exchanger has an “installation reserve” to be processed by the installer. The panel also has a space for entering the external sheet temperature sensor. The installation of the exchanger is prepared for connecting it in parallel with other heat exchangers (in other panels): through supply and partition collectors. This type of panel strengthens the roof load capacity and eliminates the thermal bridge of the lower lining (the sheet of the lower lining must be cut – the OSB not). It is also easier to fasten the finishing linings to the roof.

Available dimensions and thermal parameters

Both Thexpan® and Thexpanplus® are produced in a net width of 1.1 m, length 1 – 12.5 m and in the following thicknesses of the PUR core *:

- 100 mm (U=0,21 W/m2K)

- 140 mm (U=0,15 W/m2K)

- 200 mm (U=0,10 W/m2K)

To the total thickness of the panel it is necessary to add the linings:

- Thexpan®: 0.5mm sheet + PUR thickness + 0.5mm sheet

- Thexpanplus®: 0.5mm sheet + PUR thickness + 15mm OSB

*It is possible to manufacture Thexpan® plus panels of non-standard thickness on special order.

Features and advantages

Thexpan®, in addition to all the features characterizing sandwich panels (i.e. finish, construction and insulation in one), also has a series of other advantages which are not offered by other manufacturers. From among them it should be mentioned:

- possibility of use as a heat exchanger integrated into the roof / wall housing for heating or cooling

- increased insulation (average core density is 42 kg / m3 and not 32 as in standard sandwich panels)

- higher load capacity of the panel (thicker re-profiling and self-locking roof clip)

- no visible connectors (hidden under the clip)

- possibility of laying on flat roofs (hidden sealing under the clip)

- passive connections (hidden sealing under the clip)

- ready-made external finish

A special feature of the Thexpan® sandwich panel is the possibility of laying a roof with a slope of less than 5%. None of the other systems gives such a chance without leakage. Thexpan®, thanks to the sealing systems invented by us and the shape of the roof lock, allows you to seal the connection in 100% and cover it with a special closure – a self-locking clip. In this way, neither the connector nor the gasket is visible and do not create a potential source of leakage. This connection proves well also in passive buildings, because it creates a tight thermal and air partition.

Additionally in the variant Thexpan® plus:

- no thermal bridges (OSB from the inside of the roof)

- no need to cut the internal sheet during assembly

Examples of roofs covers

The Thexpan® roof can be made in any colour of sheet available in the manufacturer’s colour palette. It is also possible to order additional sheet metal for execution of roofing treatments of the same colour (from one scroll).